The account of the area's largest bike workshop is a bit wordy in places and excruciatingly sexist in tone, but fascinating in detail - for bikers and others, alike.

The article describes how:

- more bikes were produced at the Dames Road workshop than in any other factory in London

- bikes were manufactured, by hand

- ladies could perhaps understand how all these complicated things work (!)

- 2,400 bikes a year were built there

- the company had recently expanded its production facilities to embrace some of the railway arches on the other side of Dames Road

- a piece work system of payment was developed, to encourage high quality production

- the company had a broad geographic customer base

|

| Clark Brothers advert from Forest Gate Weekly News, 1897 |

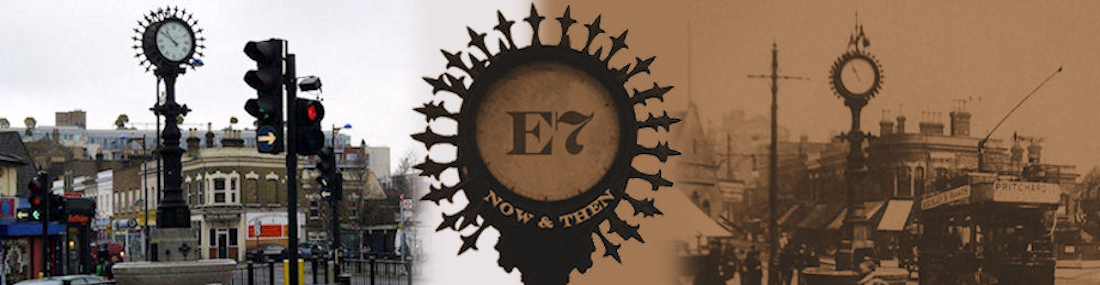

The road that bends a little out of Woodford Road, just by the Wanstead Park Railway Station and then pursues its course towards the westerly portion of the Flats is called Dames Road. So much every resident of Forest Gate knows already; and it may also be common knowledge that the thoroughfare takes its title from the Dames family who formerly owned the land thereabouts.

But what is not generally known is that a little up Dames Road behind a familiar cycle shop on the right hand side, stand is a set of works from which more cycles are turned out than from any other factory in London. They are good cycles, too, as the writer, after a careful tour through the place, and boasting some knowledge of mechanics in general and cycle mechanism and requirements in particular, is prepared to testify.

Mr. FC Clark, the managing director of Clark Brothers Cycle Co Ltd, who showed me round looks straight at you when he is talking and you feel you can rely on what he says. That is something, by way of a start. You may add to that he has been a rider, designer and manufacturer of cycles for over twenty years, and then you are quite sure that he knows what he is talking about.

We went first into the room where the steel tubing for the frames was being cut into lengths, bent as required, rolled into a D shape for the back stays and so on. It comes in 12 or 16 feet lengths (from Climax, or Perfecta Works, Birmingham - than which there are no better makers) and is sawn up like quick sticks. It is only about as thick as a card, but it takes a strong man to bend it even when he wants to.

There was one of the framemakers bending a piece across a block to form the curved tube for a lady's cycle, and you should have seen how he pulled at it. That is the beauty of a good tube. It is so thin as not to be worth talking about, and so tough that a solid bar could hardly be tougher. If it does crack under some enormous strain it cracks the way of a tube rather than across it, and you can see the long fibres of which it is composed.

Perhaps some of my lady readers who ride have not, as yet, examined their cycles with any amount of care, and do not so much know how the frames are built up. To these I may venture a little information. In the case of gentleman riders, I should not dare to be so bold. What could I possibly tell them that they do not already know? Have they not had "the thing" to pieces half a dozen times and are they not prepared to give a lecture of at least ten minutes duration with regard to every separate part of it.

|

| Site of former Clark Brothers cycle workshop, Dames Road |

So to the ladies I now explain that the frame of a bicycle consists in the main of tubers and "lugs" (The last named term is not a pretty one, but I am not responsible for it.) Lugs are made of malleable iron and are employed at those portions of the frame where one length of tubing is joined to another. The lugs are bored out to the exact circumference of the tubes which are to be let into them, and are fixed at proper angles while being bored in what is called a "jig" (Again I regret the term and again I disclaim authorship.)

There were three amazing things to me about these lugs, as I watched the boring operations in company with Mr. Clark. The first was that they could have been cast so round and so even in thickness; the second that they should, when finished, be strong enough for the work they had to accomplish.

This third point roused Mr. Clark, who was I had already found, particularly jealous of the strength of his "Winner" cycles was raised. So he took a hammer, laid one of the finished lugs on an anvil, and began pounding it. He bent it just a little, and that was all. Then he called up a man with a sledge hammer and told him to do his worst. The man - matter of fact and obedient - promptly flattened it. "now then" said I. "Precisely what I wanted to show you", said Mr. Clark. "These lugs, being made of malleable iron of the very finest quality, will bend, but they will not crack or break. And when the tube is inside them they cannot even bend."

I should have said that the group of lugs at the bottom of the frame, where the crank axle goes in, is called the bottom bracket. This is a sort of Willesden Junction and is a very useful, ingenious and important part of the machine.

When the frame is fixed together and jointed parts are brazed. Brazing is a species of glorified soldiering. The joint and the region round about are red-hot, by the liberal use of the blow-pipe, and the brass soldiers wound round on the outside of the tubes, brass filings are sometimes run down the inside of the joint, where they melt on their own account. The result is that tube and the lugs are now one and indivisible and are so destined to remain.

Upstairs there are many men at work at lathes, tuning axles, ball cups, and what not. These axles and ball cups must be turned very exact at the ball-race parts, as much of the smooth and easy running of the wheels depends upon this. Some lady readers and riders (who have not brothers) may not quite understand what these ball bearings exactly signify. If they were to be so misguided at any time as to take to pieces this particular portion of a machine they would be fully, but somewhat painfully, instructed.

They would find a lot of tiny steel balls, much smaller than peas, lying about the floor or lawn, which would give them plenty of employment and anxiety before they were safely got into their proper place again. The axles revolve amidst these encircling balls and the result is the minimum of friction and consequent resistance or wear. As a further contribution towards perfection at this part the axles are "case hardened", which makes the surface dead hard, while relieving the interior from all danger of brittleness.

|

| Locations of other cycle workshops in Forest Gate in 1890s |

Other parts of the cycle, such, for instance, as the cranks, must be extra strong; and the also the chain wheels of the "Winner" cycles are made of solid steel stampings. What think you of that, reader? The crank of your bicycle, if it is a good one, was made at one mighty blow out of a thick steel plate. Mr. Clark gets his steel (including rims, spokes, nipples etc) and also the Swedish iron for his axles, from Bunting's of Sheffield, and he does not think that better is to be obtained anywhere.

A very critical part of a cycle frame is the head, the tube for which Mr. Clark orders of extra weight and strength, and he is also very particular about the crown plates at the top of the front fork (which he makes of stamped steel) and the brazing at this part of the machine. A world of care is taken just here and with good reason. If you are going rapidly downhill, and some other part of the frame goes there may be a chance for you, but if it is the head that goes there may be a chance for you, but if it is the head that goes it will be on your own head and that the next moment will sustain violent collision with the roadway.

Messrs Clark Bros Ltd., made 2,400 machines last year, but if a single one of those had broken at the head they would not withstanding all their success be sad and sorrowful men today. While I was there a machine came in from some watering place where a young lady had ridden it sheer up against a stone wall. but the head was only bent a trifle and I was told that it would be put right in no time.

Of course I went into the room where the wheels were being built up and presently I wondered what Mr. Clark was going to do. For he got two boxes, pushed them apart, laid the opposite edges of a wheel slightly on each and stepped on to the middle. Now, Mr. Clark scales 12 stone and I heard a crack. It turned out that one of the spokes had stripped its thread at the rim. Otherwise the wheel was uninjured.

But Mr. Clark looked quite disappointed. The spoke ought not to have gone. So he called for a "hollow rim" and when this was produced he stepped upon it - both feet and free of everything - as before. Yet not a quiver did that slender, thread-like wheel give. When Mr. Clark got down the man spun the wheel on its axle and it still ran as true as a hair.

"What is your idea of a good, reliable, bicycle, Mr. Clark?"

"Westwood hollow rims, Appleby chain, Dunlop or Palmer tyres."

We went into the enamelling room and I asked Mr. Clark what his enamel was made of, whereat he only smiled. There is a range of ovens adjoining the enamelling room, and into these the enamelled parts go once, twice, and thrice. They are twice pumice- stoned, and after the third enamelling and "baking" are deemed fit for the light of day. The frames and other enamelled parts are previously ground smooth and bright upon an emery wheel with a felt circumference. This revolves at a terrific rate. You are sure to put your finger on the part being ground to feel how smooth it is and you are equally sure to take it off again pretty quickly on ascertaining how warm it is.

Across Dames Road Mr. Clark has just annexed four railway arches and added these to his works this year. They make capital workshops and are full of men pegging away as if for dear life. As a matter of fact they are on piece work. Don't be alarmed and imagine that the piece work may not be good work. There are some smart foremen walking about and bad work pays the foremen the least of any. For they get nothing for it.

|

| 1899 advert for Forest Gate cycle shop/workshop. Advert designed by Ward and Co, also of Forest Gate |

At least twenty of the men employed by Messrs Clark Bros Ltd ride machines of their own making and of the "Winner" type. The firm rather encourages this. Of course, a frame maker cannot do turning and a turner is not a frame maker. So, one helps the other and the firm charges cost price for the whole. The two months prior to the December shows are the best times for this sort of work, for those are the dead months of the year. But the cycle trade is becoming more and more a whole year trade.

"What is the proportion of ladies' machines to gentlemen's machines in your works?", I asked.

"Half and half last year. This year we expect to make has as many more ladies as gentlemen's. You would scarcely credit the trade we are doing with ladies in such places as Wanstead, Woodford, Snaresbrook and that direction.

Mr. Clark showed me several machines already made to order for the coming season - one for a Wiltshire MP, another geared to 104 (!) for a Glasgow record striver and another beautifully enamelled in gold and colours for another customer at a distance.

"Then your trade is not altogether a local one?"

"Quite the contrary. But this year we intend to cater more thoroughly than ever for Forest Gate and the surrounding district."

At which I expressed my gratitude and said that I would send our advertisement man round."

For details of the seventeen cycle workshops in Forest Gate at the turn of the twentieth century, see here.

So, cycle manufacture was a significant activity in Forest Gate 110 years ago - what happened to the output? For some local details, see next week's blog, where we take you on a spin of the area.

No comments:

Post a Comment

We welcome comments to all the items featured on this site. However, we reserve the right to omit offensive comments, and edit the length of comments, for reasons of space.